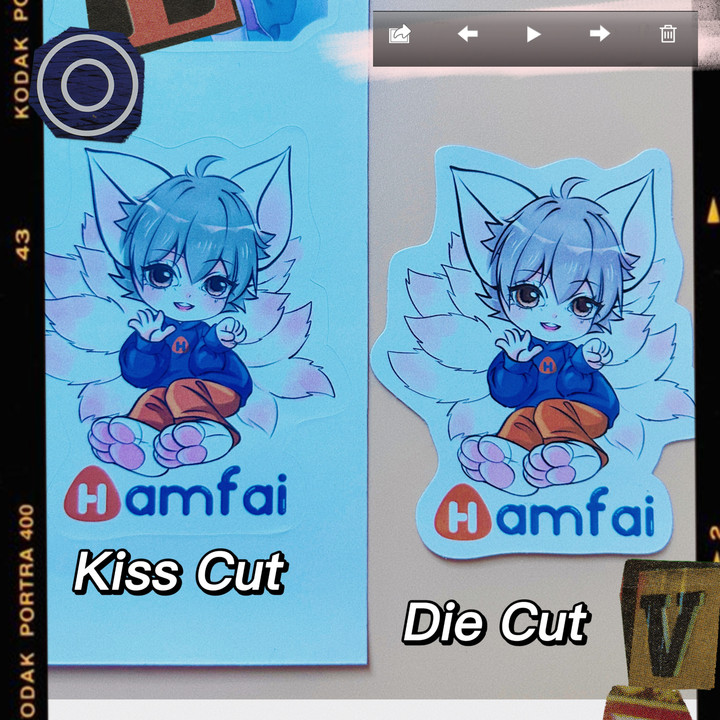

what’s the Difference between Kiss Cut Stickers and Die Cut Stickers

Kiss cut stickers and die cut stickers are two common ways of stickers cutting formats, and they have some notable differences in how they are cut and how the stickers are presented. Understanding these differences can help us choose the type of sticker that suits our specific needs.

Kiss Cut Sticker

Kiss-cut sticker is a partially cut sticker that cuts through only the sticker material while leaving the adhesive backing intact. This style of cutting is called a “kiss cut” because the cutting pressure is light and touches the material lightly. Kiss-cut stickers are usually presented on self-adhesive paper, with the individual stickers enclosed within the edges of the uncut material. This makes it very easy to remove the stickers from the adhesive backing while keeping the stickers organized and protected. This makes kiss-cut stickers popular for promotional items, product labels, package stamps, and more.

Advantages of kiss cut stickers

Ease of use and distribution: Kiss-cut stickers are usually more flexible, can contain multiple stickers on one sticker paper, and are suitable for high-volume mass production and distribution. They are often used in promotional materials, product labels or giveaways. The back panel provides stability, making it easy to peel and distribute stickers. Kiss cut stickers are available in a variety of sizes and shapes, making them suitable for a wide range of applications.

Lower production cost: The production process of kiss-cut stickers is relatively simple, only need to cut the sticker layer instead of the adhesive layer. This makes kiss-cut stickers relatively inexpensive to produce and suitable for mass production and customization. In contrast, the production process of die-cut stickers involves cutting the adhesive layer and the sticker layer, which may require more complicated equipment and processes, resulting in slightly higher production costs.

Die Cut Sticker

In contrast, die-cut stickers use steel cutting dies that precisely cut the sticker material to create custom shapes and designs. The cutting process penetrates the sticker material and the adhesive backing material to form individual sticker shapes. Die-cut stickers are usually presented as individual stickers with no surrounding material. They can be cut into stickers of various shapes and complexities according to design needs, making the stickers stand out and catch the eye. Die-cut stickers offer more flexibility in shape and complexity.

Advantages of die cut stickers

Versatility: They can be customized to match specific designs, logos, or artwork, offering endless creative possibilities. Die-cut stickers are available in a variety of materials such as vinyl, paper, or special finishes such as holographic or metallic options. They are durable, weather resistant and suitable for both indoor and outdoor applications.

Small batch customization: Since die-cut stickers can be made through molds, it can meet the needs of small batch customization. This makes die-cut stickers ideal for personal customization, special events, or small-scale productions. In contrast, kiss-cut stickers may be slightly less flexible and economical for small-volume customization.

Choose the correct sticker

The choice between die-cut and kiss-cut stickers depends on your specific requirements, and hamfai can provide you with the best choice. If you are looking for low-volume custom stickers, die-cut stickers can be your first choice, providing a professional and unique look. Commonly used for brand identity, stickers for special events, personalization and more. On the other hand, if you need stickers that are easy to distribute or apply, kiss-cut stickers are a practical choice. They’re perfect for promotional material, packaging, or a lot of stickers that need to be organized for distribution. Commonly used in product labels, packaging seals, promotional materials, etc.

To sum up, die-cut and kiss-cut stickers each have their own advantages and application values. Whether you want to mass produce and distribute stickers, or you need designs of custom shape and complexity, kiss-cut stickers and die-cut stickers offer a variety of options to meet various sticker needs. Knowing the differences between these two cutting techniques can help you make an informed decision when choosing the right sticker for your specific needs.